Most conventional vacuum dryers are drum-type used for batch processing. Usually, batch operation by these dryers requires a long processing time in a vacuum of 1 - 20 Torr (mm Hg-abs) with feed and discharge being controlled manually. As heat only comes from the drum jacket, the treatment of a large quantity of material is difficult for these dryers.

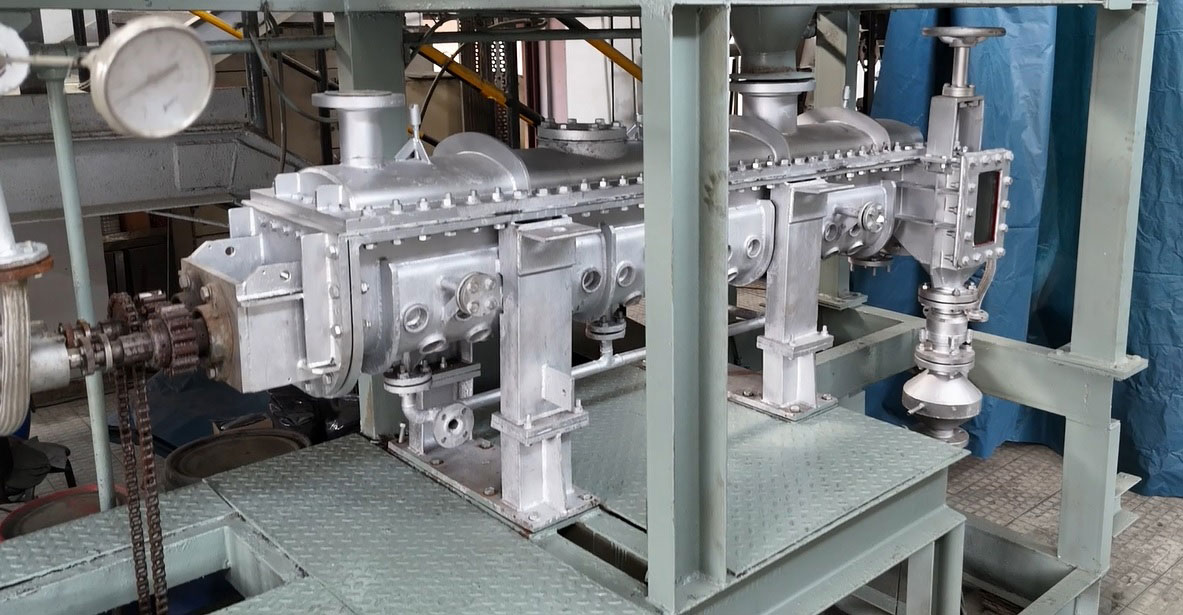

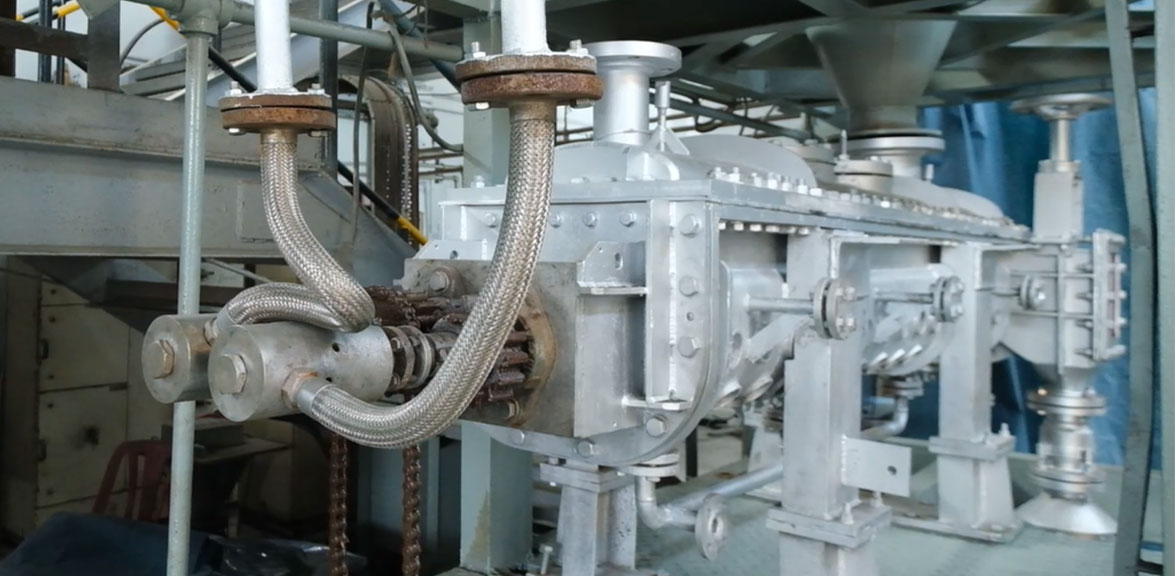

In order to overcome this disadvantage, continuous vacuum paddle dryer is developed by Kilburn. This system has the features of conventional vacuum dryers and also the process is automatic, continuous and efficient. In addition, the vacuum system realizes a high heat transfer efficiency with vacuum maintained at approximately 10 - 200 Torr.