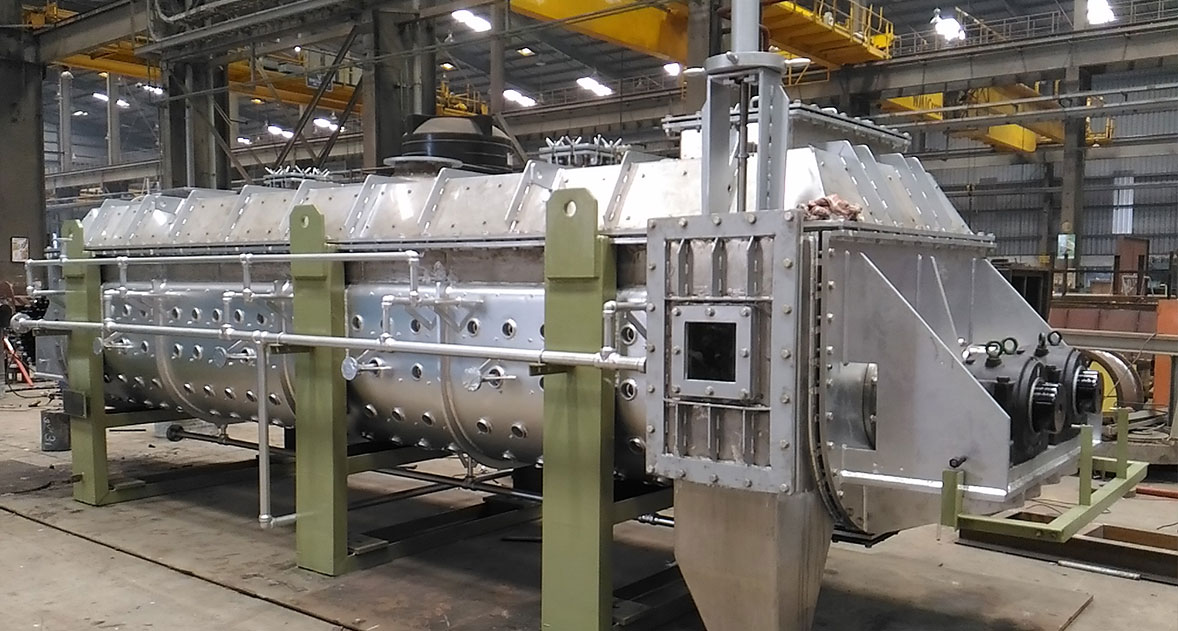

This dryer is a conduction-type dryer that is indirectly heated and has very high thermal efficiency. It comprises two hollow shafts joined together by a set of open uniform-shaped paddles that rotate inside a jacketed shell.

Drying sludge from a centrifuge or filter press is made simple and effective with KILBURN Paddle Dryers.

High thermal efficiency, self-cleaning paddles, minimal dusting, lowest cost of drying, and the ability to dry sludge to less than 5% without back-mixing with sludge moisture up to 90% are all features of this device

Depending on the type of sludge treated, the paddle dryer's construction material can be either carbon steel or stainless steel grade 304L or 316L. A specific abrasion-resistant lining is also placed on the paddle surface when processing abrasive sludge

KILBURN offers a variety of paddle dryer models based on heat transfer area for differing handling capabilities.

The test facility at KILBURN has a pilot plant accessible for conducting trial with customer's material.